-

Repair Turnaround

Choose between our Express or Standard turnaround when you book a repair.

-

2 Year Warranty

Our industrial electronic repairs are backed by an inclusive 2 year warranty.

-

NO FIX NO FEE

Our unique No Fix No Fee promise is exactly as it sounds, if we can't fix it you don't pay a penny.

-

FAST RETURN DELIVERY

We return ship all your goods on FedEx priority service. All of our shipments include tracking numbers.

-

UP-FRONT PRICES

Search your part numbers to see up-front repair prices displayed online for thousands of products.

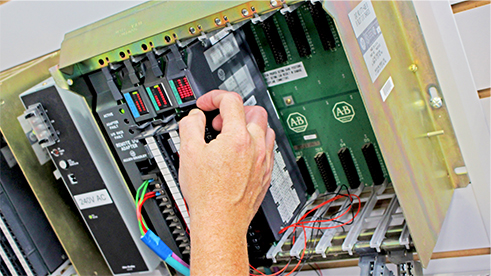

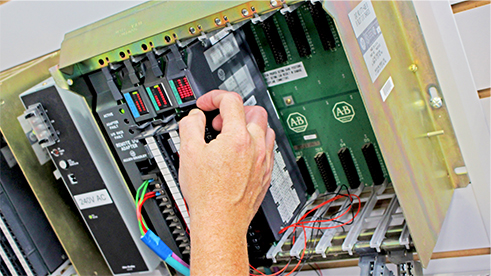

In-depth PLC Repairs

Together with our 20,000 sq ft repair facility, bespoke test rigs and highly trained PLC repair engineers, we seek to provide the most efficient and cost effective solution for all types of PLC modules:

- > CPU modules

- > Power supply modules

- > I/O modules

- > Interface modules

- > Communication modules

- > Memory modules

- > Special function modules

- > Expansion modules

- > Programming devices

Customer Reviews

PLC repair test facilities

With extensive in-house test facilities, adapted to suit each project’s requirements, Northern Industrial will ensure your PLC is returned to you repaired and ready to go!

Our electro-mechanical and cosmetic rebuilds are undertaken right down to component level by specialist electronics engineers. And with our award winning PLC repair test facility accredited to British and International standards, including ISO 9001 certification, you can be sure of our quality.

PLC Repair Process

Step #1

Check price & book your repair online

Step #2

Package up your part for collection

Step #3

We’ll collect your faulty part

Step #4

Your repaired part will be returned within the specified turnaround

Legacy system support

We understand that just because a manufacturer has made a range obsolete, it doesn’t mean you are able to upgrade straight away. This is why we offer our support to users of legacy systems long after the original manufacturer. We specialise in providing ongoing support to companies whose production processes are reliant on end-of-life programmable logic controllers.

PLCs reach the end of their Product Life Cycle for a variety of reasons. Parts or resources may no longer be available, new technology may offer new solutions or the products are no longer economically feasible for the OEM to continue supporting.

Program Backup

As part of the repair process, Northern Industrial has worked with clients to introduce better working practices and product improvements. One such improvement, when possible, is to backup the customers program and parameters before repairing the faulty PLC module. For some customers, the program is often more valuable than the hardware and being able to back it up means you can get back up and running in as quick a time as possible as there is no need to reprogram your PLC.

Want more information?

Our team will contact you.