Has Additive Manufacturing Earned Its Racing Stripes?

Published: 06/01/2023

Has Additive Manufacturing Earned Its Racing Stripes?

In a competitive industry such as motorsport, optimising the manufacturing process and enhancing the end product is crucial to securing a place on the winners podium. Like in many fields, continuous improvement and innovation is key and additive manufacturing is clearly making its mark. With performance on the track being dictated by the vehicles durability, reliability and most notably, its aerodynamically efficient design, 3D printing is the solution for teams aiming to accelerate towards victory.

What Are the Main 3D Technologies Used in Motorsport?

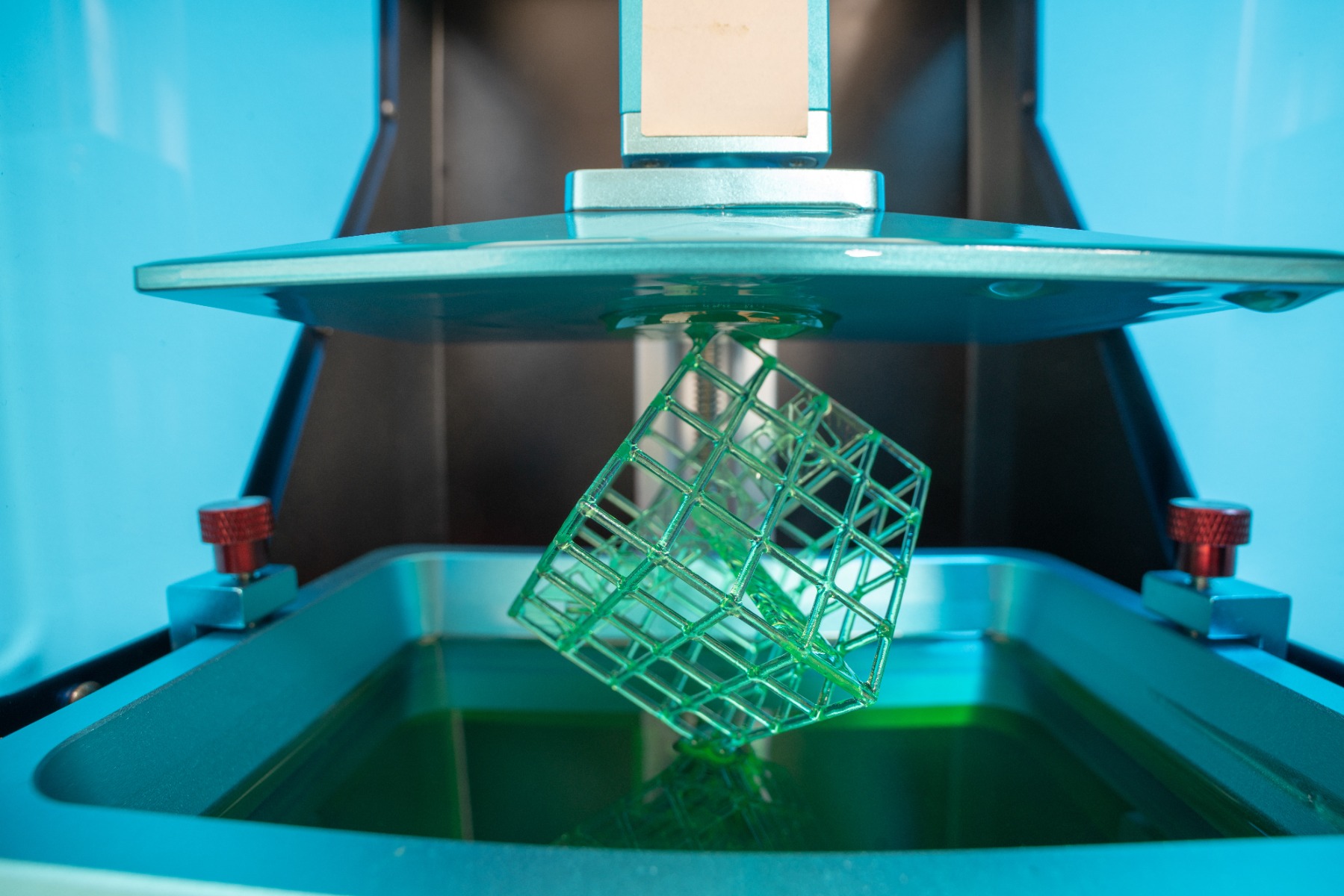

Over the course of time, we have witnessed the world of printing undergo a periodical metamorphosis with enhanced speed, simplified human intervention and an increasing number of industry applications. Holding the top three positions in the motorsport field, stereolithography (SLA), fused deposition modelling (FDM) also known as fused filament fabrication (FFF) and powder bed fusion (PBF) are the most prominent technologies present in the world of additive manufacturing.

So, what’s the difference? While our first two contenders are more cost effective, the latter poses excellent benefits when it comes to precision and durability. The choice is entirely dependent on the component which is being manufactured, its usage and the complexity of its design.

Curious about how these techniques are used in other industries? Click here.

How Is Additive Manufacturing Entering the Motorsport Industry at Full Throttle?

Additive manufacturing has long been criticised for its low production volume, forming a barrier between it and mass manufacturing. However, when it comes to motorsport where only a few race cars are used per team, smaller scale operations are employed, making 3D printing the ideal technology for their needs. It is worth noting that ultrafast 3D printers are now infiltrating the additive market, capable of significantly reducing print times. From component design using innovative materials throughout the prototyping stage to producing replacement parts in record time, additive manufacturing has gained significant traction in the sport.

3D printers Wohlers conducted market research which revealed that just over 16% of all 3D printing carried out in 2015 was attributed to the automotive industry. Six years later, it is safe to say that this number is inflating. Rapid prototyping at lower costs becomes a possibility and customisation transforms into an endless realm. This form of robotic manufacturing allows for the condensing of the supply chain with OEMs utilising 3D printing as opposed to waiting for third parties to import finished automobile components.

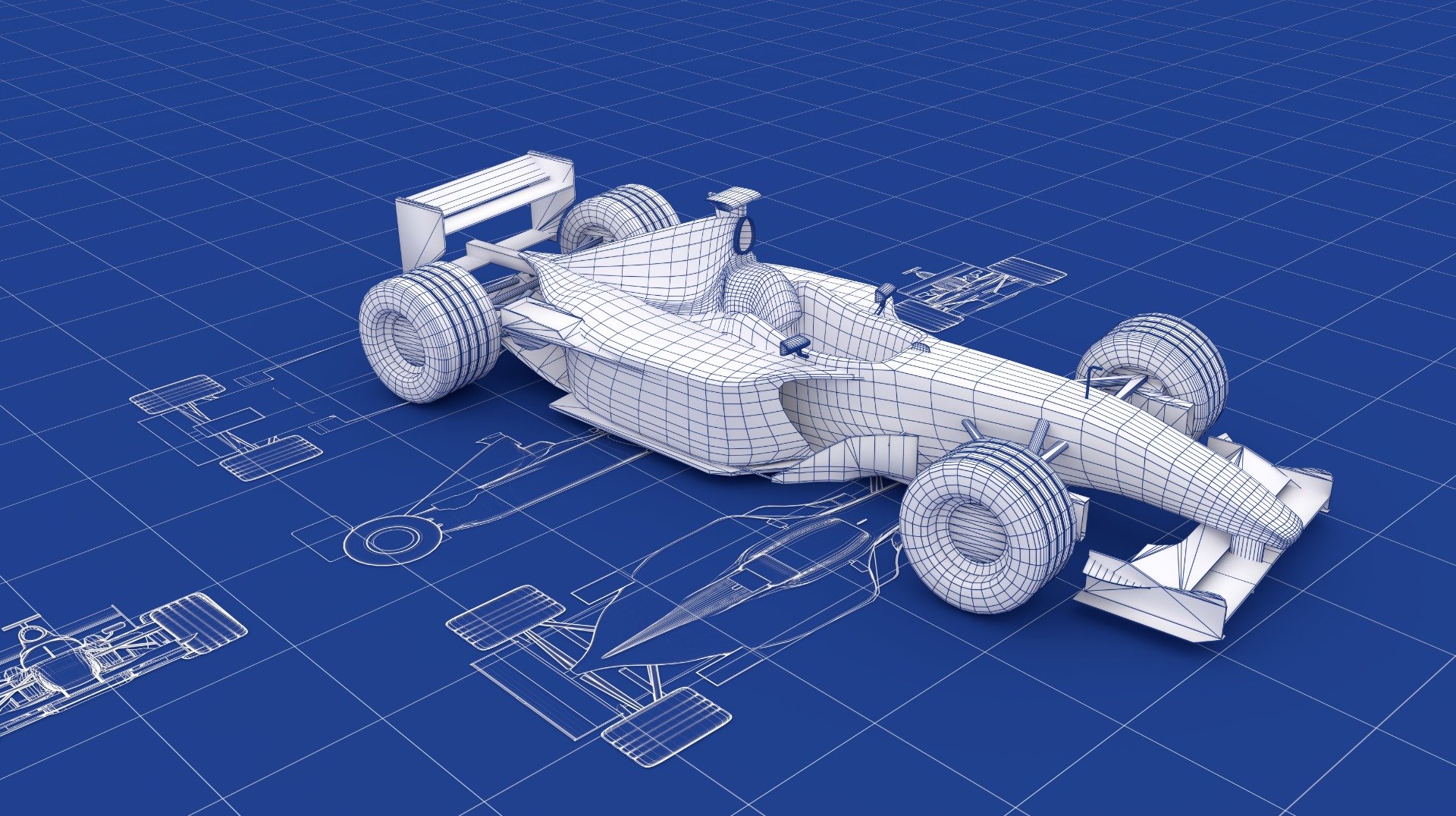

With innovative design, comes greater competitive advantage. Getting ahead of the curve relies on being able to design or redesign components quickly. The longer the design process, the more chance there is of being pipped to the post by a competing team. In a scenario where an engineer has a concept in mind, it would traditionally go through many stages of trial and error before being produced, however with CAD technology and 3D printing, even the smallest of modifications can be made in an incredibly short time frame.

Additive manufacturing also allows for far more complex concepts to become a reality. Parts must remain accessible to the pit stop team while also being incredibly compact as to not stunt aerodynamics. Therefore, being able to optimise lightweight component geometries, further enhances aerodynamics, reduces fuel consumption and enables the driver to cross the finish line rapidly, all while allowing access for in-race repairs if needed.

Whether it be in the manufacturing process or on the circuit, speed is key. In many cases, design teams are required to manufacture intricate parts in under 24 hours, making 3D printing an integral piece of the puzzle. Prototyping is crucial to this process. By inputting data into computer-aided design (CAD) software, the programmer is able to map out each detail of the part, making adjustments where needed at great speed. Traditionally, the engineer would have to prepare the mould prior to manufacturing the part, however using CAD, the production process is far faster. These components are then tested in wind tunnels, ensuring the new parts maximise downforce and minimise drag, becoming as aerodynamic as possible. The wind tunnel essentially creates a simulated replica of real life track scenarios, with a conveyor belt travelling at an adjacent speed to an industrial fan, analysing the effectiveness of the prototype using sensors.

With engineers designing a new car annually on average, rapid component creation is a major innovative player. Overall, prototyping is incredibly fast, cost-effective all while offering deep insight into product development. Although additive manufacturing is most prominent throughout the product development and prototyping stages, these printed parts are making their way onto the track as end-use components.

Does your additive manufacturing process qualify?

No matter your automation requirements, we have you covered. From replacement sensors and HMIs to drive repairs and obsolete spare parts, we are committed to fine tuning your 3D printing operations.

Industrial automation is part of our DNA. If you are on the hunt for a complete automation solution for your additive manufacturing process, we are ready and waiting to provide the support you deserve.

Want to find out more?

If you'd like to learn more, click the button below and one of our helpful friendly team will be in touch. Alternately you can reach us by phone on +44 800 234 3747

Share this article