The History of Industrial Automation

Published: 29/10/2021

The History of Industrial Automation

In an ever-changing world of new technologies propelled by innovative ideas, the cogs of industrial automation have not ceased to turn.

Each development in the world of industrial automation has enabled varied industries to harness the power of the machine, boosting accuracy and precision. These developments build on the established foundations set by industry pioneers, cementing countless bricks in place to achieve pivotal milestones.

The concept of automation can be traced back more than two thousand years ago when the Chinese utilised water wheels to power trip-hammers, followed by early Greeks who conceptualised reaction motors powered by steam. It was Greek poet Homer who devised the term ‘automation’, mentioned frequently throughout Greek mythology in reference to a self-moving chariot. Even folks during the 11th century embraced hydropower as a means to drain water from underground tunnels. The concept of automation was born and lay in wait until the dawn of the 18th century, paving the way for significant developments in the coming years.

The Dawn of Mechanised Factory Systems

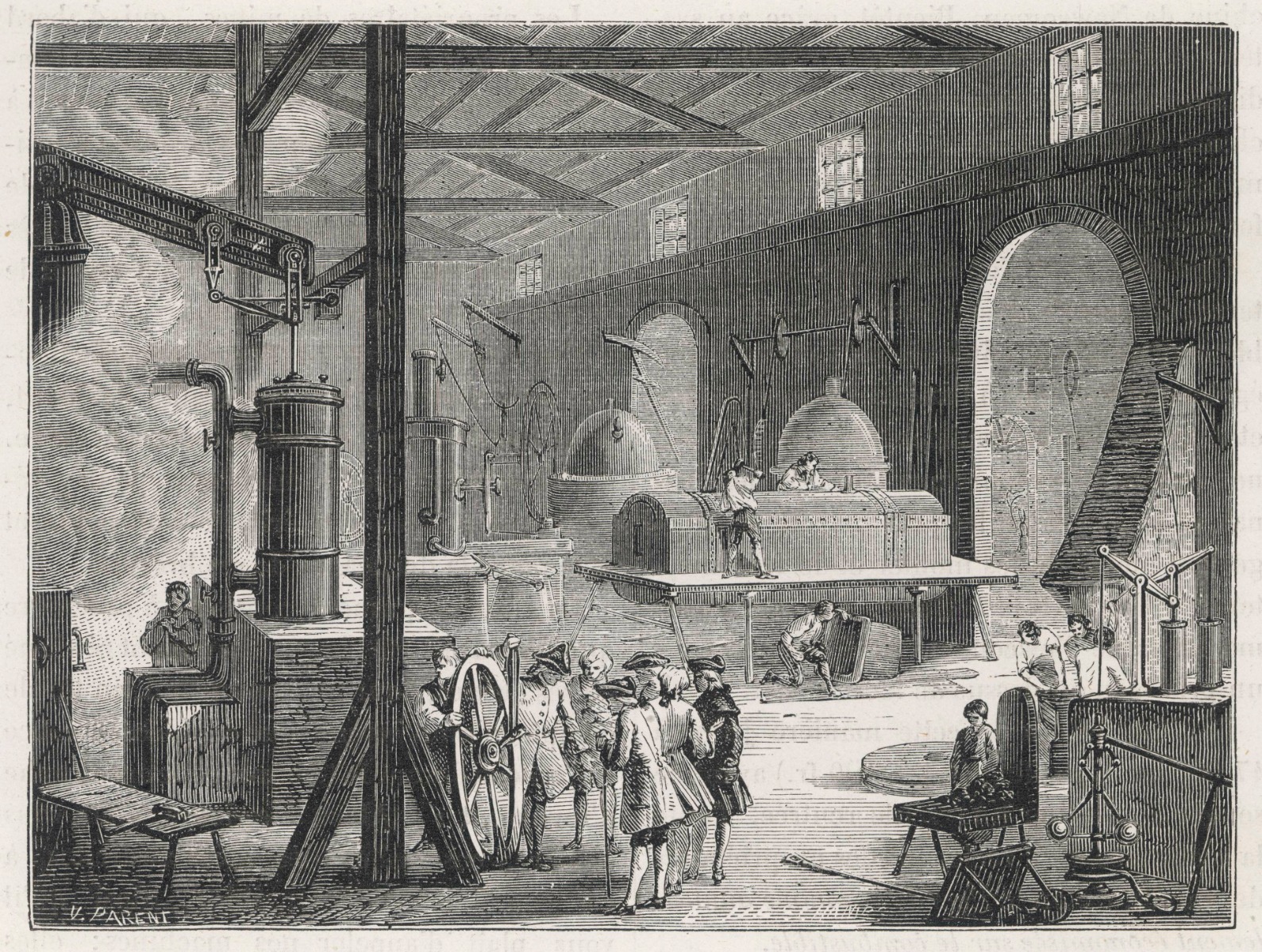

The 18th century bore witness to the First Industrial Revolution, evolving from manual labour to the rise of the mechanised factory system.

Blacksmith Edmund Lee patented the world's first feedback control mechanism in 1745. With his roots firmly planted in the North West (Wigan to be exact), he employed windpower using his fantail design. Soon after, Boulton and Watt made their mark in the industrial automation field, maintaining engine speed by controlling fuel supply, revolutionising manufacturing processes as pioneers of the industrial revolution.As the 18th century drew to a close, Joseph Jacquard invented ‘punch cards’ in 1801, fashioned to instruct mechanical looms of their pattern instructions. Following in the French weavers footsteps and basing his design on the programmable "Jacquard loom", Charles Babbage began a journey to create the first programmable computer christened ‘The Analytical Engine.’ Being close friends with Babbage, Ada Lovelace became the first computer programmer, which theoretically would have run on his machine. The idea that providing simple instructions allows the computer to carry out a complex calculation was a revolutionary concept which would have a remarkable impact on the industry.

Sparking Change: The Electrical Inception

The 20th century played host to a transformative shift to a radically different industrial landscape as the Second Industrial Revolution loomed. The revolution brought with it the introduction of electricity, allowing mass production concepts to bloom. This shift required the development of electronic systems and so in the early 1900s, Alexander Graham Bell facilitated such innovation. Creator of the telephone system, Bell began to develop the transistor, which continues to be “one of the basic building blocks of modern electronics to this day.”

Since its inception, the global automation industry benefited greatly from developments in industrial automation as Ford Motor Company introduced a car production assembly line in 1913, reducing assembly time from twelve hours to just under one hundred and twenty minutes. From boosted production rates to increased profitability, the benefits were endless. Twenty years later, the usage of feedback controllers was on the rise, and by the 1940s, the term “automation” was becoming far more commonplace.

A Century of Innovative Inventions

As the Second World War ended, the 1950s formed a triad of industrial revolutions, now incorporating more electronic technology into factories. In the following years came countless firsts, beginning in 1968 with one of the most significant developments in industrial automation, the Programmable Logic Controller. Invented by Richard Morley and his team, once the Modular Digital Controller (MODICON) was implemented in the manufacturing process, results demonstrated a 60% reduction in operational downtime. The Distributed Control System (the brainchild of Honeywell engineers) followed just a few years later along with HMI software and sensors contributed to by various innovative parties.

These leaps in industrial automation led to the concept of ‘lights-out manufacturing’ in the 1980s, an idea born in the automotive industry. The competitive market aimed to kick their competition to the curb by promptly supplying growing demand by employing an automated process, capable of performing repetitive tasks with unrivalled precision. This notion of transforming the manufacturing process and minimising the risk of human error was a vision for the future, a pipe dream. As we entered the 21st century, so much progress had been made over the past three decades and significant steps had been taken to make this vision a reality.

Digitising Industrial Automation

The Fourth Industrial Revolution represents a paradigm shift, building on the legacy of the third and embracing all things digital. Klaus Schwab of the World Economic Forum characterised it as “a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres” in 2016. In a world of such dynamicity with an intense focus on technology, it comes as no surprise that the internet of things, artificial intelligence and this amalgamation of technologies is shaking things up and spearheading the Industry 4.0 movement.

Throughout the historical timeline of industrial automation, humans have been taught to communicate with machinery via interfaces, enhancing the manufacturing process and automation has been achieved by many varied means. From mechanical and pneumatic to hydraulic and electrical, the combination of these automated techniques has been revolutionary for global industries when developing computer integrated manufacturing processes.

Entrepreneurial individuals and companies have been recognised as trailblazers of the movement in their collaborative effort to innovate industrial automation operations. The past has been a driving force behind seizing current opportunities and if the previous years are anything to go by, progression in the industrial automation field is showing no sign of hitting the brakes.

No matter your automation requirements, Northern Industrial has you covered. From drive repairs and HMIs to PLCs, obsolete spare parts and everything in between, we are committed to optimising your operations.

Industrial automation is part of our DNA. If you are on the hunt for a complete automation solution, we are ready and waiting to provide the support you deserve.

Want to find out more?

If you'd like to learn more, click the button below and one of our helpful friendly team will be in touch. Alternately you can reach us by phone on +44 800 234 3747

Share this article