-

ABB

-

Allen Bradley

-

Control Techniques

-

Danfoss

-

Lenze

-

Mitsubishi

-

Siemens

-

Yaskawa & Omron

Supported brands

We support all the major brands and ranges commonly found in industrial environments as well as more obscure, obsolete AC inverter drives.

Customer Reviews

-

Repair Turnaround

Choose between our Express or Standard turnaround when you book a repair.

-

2 Year Warranty

Our industrial electronic repairs are backed by an inclusive 2 year warranty.

-

NO FIX NO FEE

Our unique No Fix No Fee promise is exactly as it sounds, if we can't fix it you don't pay a penny.

-

FAST RETURN DELIVERY

We return ship all your goods on FedEx priority service. All of our shipments include tracking numbers.

-

UP-FRONT PRICES

Search your part numbers to see up-front repair prices displayed online for thousands of products.

Our Repair Warranty

Cutting corners is easy. Since our warranty is all inclusive and covers the entire drive, not just the parts we change, we do a full preventative maintenance service. This involves replacing all serviceable components that degrade with age, such as capacitors and fans, to prolong the lifespan of your drive.

INVERTER DRIVE Repair Booking Process

Step #1

Check Price & Book

Search your part number for up-to-date repair prices on thousands of parts. Then contact us to arrange a collection or to discuss your industrial electronic repair requirements with one of our technical team.

Step #2

Package up your part for collection

Then all you need to do is package up the item ready for our courier. Don't forget to fill out our repair request form to let us know all the faults you're experiencing.

Step #3

We’ll collect your faulty part

We will contact you to let you know when your item will be collected. Now all you have to do is hand over the package and leave the rest to us.

Step #4

Receive your repaired parts

Once your repair is complete we will contact you to arrange payment. Your item will be returned with free shipping. For increased longevity and peace of your mind your repair will benefit from a 2 year warranty and a full service.

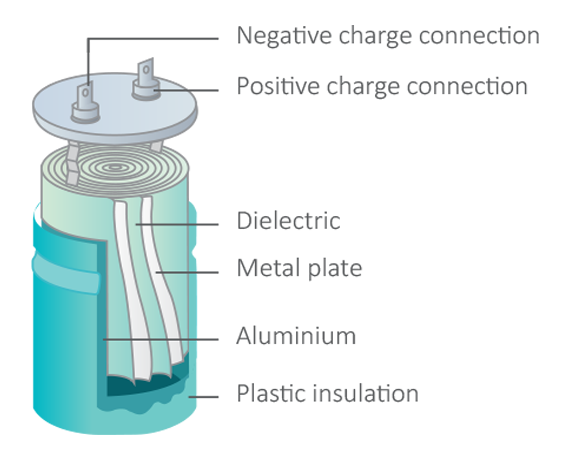

The Capacitor

Capacitors are found in every drive we repair and are unfortunately one of the root causes of drive failure.

The liquid electrolyte in each capacitor dries out over time, lowering the ESR until the caps blows. Depending on the environment your drive is kept in, this process can accelerate, directly affecting the lifespan of your drive, which is why we replace them for new ones.

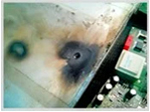

This Is What Happens When Your Caps Go Bad ...

#1

Before the unit is even fully disassembled you can see the capacitor has blown a hole through the side.

#3

You can see the inside of the capacitor has blown through the full length of the drive.

#2

As the liquid electrolyte dries out the ESR lowers until the caps blows, in this case spectacularly!

#4

You can see the hole it's made as the leg of the capacitor has shot straight through the steel side plate.Testing Variable Speed Drives

Testing is an important part of the drive repair process which is why we test each drive under load for several hours before it is returned to you.

We've dedicated a lot of time developing test rigs to functionally test drives in a vast power range to ensure only functioning inverter drives leave our repair facility.

-

Component Drives

Before we reassemble a drive we individually test each component to be sure the fault is eradicated. -

Bespoke Test Rigs

Our bespoke test rigs fully functionality test many different brands and ranges. -

Back It Up

Our bespoke test rigs fully functionality test many different brands and ranges. -

Load Testing

The last step of any inverter is to load test the drive for several hours before we return it to you.

Request A call Back

Submit your details and one of our team will call you back to discuss your repair requirments