The Battle for Control: Soft Starters Versus Variable Frequency Drives

Published: 18/02/2022

The Battle for Control: Soft Starters Versus Variable Frequency Drives

When making the decision between a soft starter and a variable frequency drive, they seem virtually the same on the surface.

It is only when we take a closer look at the functionality and capabilities of each device that we see their true potential. Both have a way of controlling current and the amount of power reaching the motor and both pieces of equipment can prevent power surges. The way in which they are distinguishable is how they function to follow this operational process.

Spot The Difference

When choosing between a soft starter and a variable frequency drive, we must delve into the inner workings of each device.

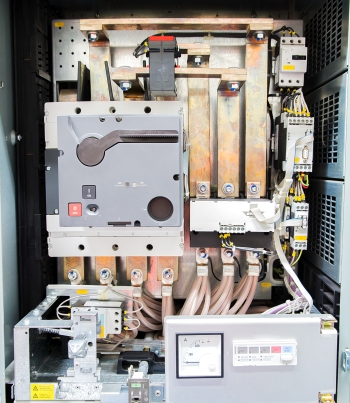

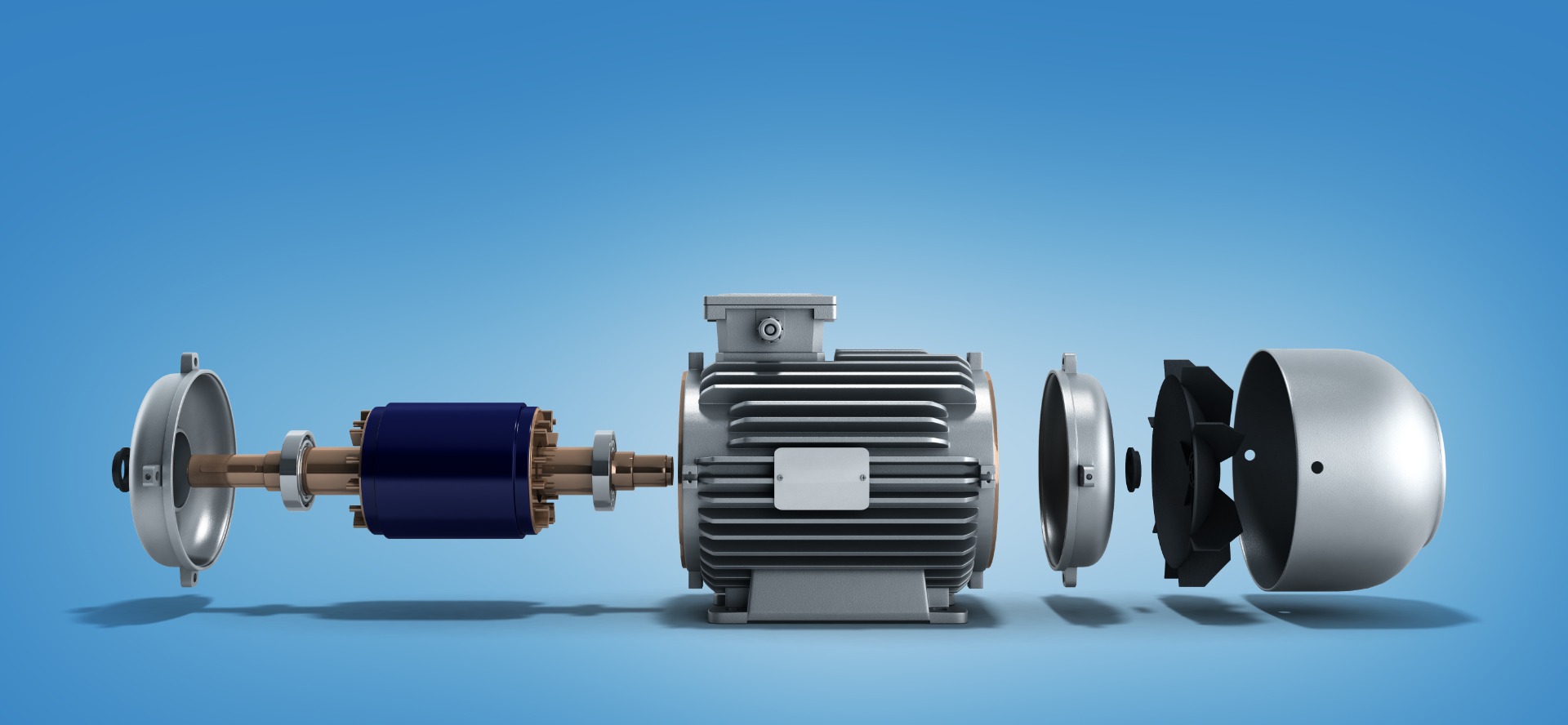

A soft starter (typically a three phase device) consists of six thyristors, capable of starting the motor smoothly, avoiding any bumps in the road to reaching the desired level of power. The thyristor is a solid-state semiconductor device and within it, are three elements. The cathode and anode work in conjunction with the logic gate to achieve this gradual effect. Once a pulse reaches the logic gate, it opens allowing current to flow from anode to cathode and finally to the motor. Having thyristors applied to the motor means they can be turned off, blocking the pulse from reaching the gate and restricting the level of current which gets to the motor. Instead, the current will gradually reach the motor, allowing it to slowly start until it reaches maximum speed before slowly decelerating in the same manner.

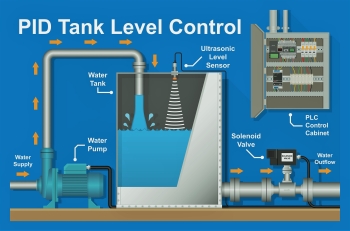

The AC variable frequency drive also has a triad at its core, consisting of a rectifier, filter and an inverter. The process is as follows; the rectifier transforms AC to DC voltage, enters the filter which cleans it using capacitors to provide smoother power, finally making its way to the inverter where transistors are used to transmit this DC voltage to the motor in Hertz format. Similar to soft starters, variable frequency drives are capable of communicating with the motor to establish a specific RPM.

In a nutshell, the difference is the speed at which the motor is permitted to run. The variable frequency drive slowly starts the motor and then provides you with the option to maintain control over this speed. In contrast, the soft starter slowly starts the motor until it reaches full speed (or the programmed speed) and continues to operate at this speed until finishing its process.

What are the deciding factors?

A question on the minds of many Maintenance Managers is “should I use a soft starter or a VFD?” Well, the conclusion depends entirely on your specific requirements and how you like to run the show.

Do you require complete control over each stage of a process?

The variable frequency drive has more speed customisation, however if your process requires control just during the start up and power down, a soft start will be ample.

What available space do you have on site?

Just a heads up, soft starters are usually more compact in design than VFDs, so if you are lacking in space and it suits your needs, this may be the one for you.

Which device fits into your budget requirements?

The soft starter is priced lower but the VFD has enhanced features meaning there is a higher initial outlay. However, the long term financial savings may tip the scale in its favour.

The above covers the additional factors to consider when making such a dividing choice, however the main consideration is the application. Whether it be in an industrial automated system or within a commercial building, the device chosen to kickstart a motor is crucial to ensuring a smooth process. Variable frequency drives or soft starters are essential technologies across a vast array of industries and applications.

The manufacturing industry is arguably the most impacted by this decision. Many production lines are required to fulfil high levels of demand, accurately producing products of consistently high quality. Surface mount technology moves designated components into the desired location and is one of the most commonly used pieces of kit in the industry. The addition of a VFD allows this movement to be incredibly precise as the motor is informed of the location to place the component. The process is smooth and completed in the blink of an eye. The uses of a VFD traverse beyond the actual manufacturing process and into the realm of packaging the goods. The motor has a rotating capability and when controlled by the VFD, is even capable of constructing the packaging itself into box form using robotic arms. If you think the use of a variable frequency drive ends there, you are way off the mark. Once ready for delivery, the products are then moved to the distribution area and where this cannot be done manually, a motor is used. As the operator increases the load, the VFD allows the drive to control torque, providing a steady and smooth delivery. To summarise, this device heavily impacts each stage of manufacturing from the mass production of goods to the haulage of items, optimising your automation process.

While both soft starters and VFDs can be used to safely and efficiently start and stop a motor, the VFD does have the advantage if you also wish to control output frequency for your diverse workloads. If your situation sounds like the above example, it is likely that a VFD is your chosen one and with reported energy savings of over 20%, it certainly would not hurt the budget. Specifically in processes using pump and fan mechanisms, a 10% reduction in speed is shown to reduce energy usage by 33%. However if you require high current and torque for a motor driving a large load, chances are that the soft starter will quell your power surge worries. With a lower purchase price and likewise reduced energy costs, whatever your decision, there are savings to be had.

Taking Control of Your Final Decision

To summarise, there are fantastic benefits of both soft starters and variable frequency drives, but when push comes to shove, the verdict is purely down to your personal needs and it is impossible to say that one is superior to the other. The variable frequency drive can master the slow start and stop just like the slow starter itself, but it has an additional tier of customisation and control. If you currently have a soft starter installed and your operational needs have changed, replacing it with a VFD is plain sailing. Likewise, if you are simplifying your process and no longer require that level of continuous control, a soft starter can be installed to replace your VFD.

The main benefit reaped from a VFD is the reduced levels of energy used as the speed is controlled by the device throughout the entire process, limiting the speed of the running cycle. Lower energy consumption equates to less pennies flying from your budget. Avoiding power surges is also front and centre when making this operational decision. Able to control the speed throughout using a VFD, this means that you are reducing the likelihood of encountering the dreaded power surge which is likely to translate into downtime and yet more damage to your budget. If you do not need to vary the speed of the motor throughout the process once started, a soft starter will certainly do the trick. Whichever option you come down in favour of, installing a starter will protect your motor and each component which it powers, limiting exposure to sudden inrush current and voltage sags.

We are second to none when it comes to the supply and repair of variable frequency drives and soft starters, ready and waiting to support you in making the decision.

The Northern Industrial team can give you the impartial advice you need to select the right soft starter or VFD for your electric motor.

New and reconditioned drives from current and obsolete product ranges can be found in our online store in addition to fixed price repairs.

Want to find out more?

If you'd like to learn more, click the button below and one of our helpful friendly team will be in touch. Alternately you can reach us by phone on +44 800 234 3747

Share this article