Automation in the Pipeline: How Has SCADA Refined the Oil and Gas Industry?

Published: 14/04/2023

Automation in the Pipeline: How Has SCADA Refined the Oil and Gas Industry?

Oil and gas automation, termed oilfield automation, can transform an incredibly complicated and intricate process into a far more simplified, data centric operation. Supervisory Control And Data Acquisition, most commonly known as SCADA systems, have completely transformed the oil and gas industry, forming a symbiotic relationship between automated technologies and the production process. How does it work? In short, sensors measure and control the parameters of equipment, acquiring the data which is then communicated to the programmable logic controller (PLC) or remote terminal unit (RTU) before finally translating it via SCADA software to the centrally located human machine interface (HMI) in a visual format. From here, data can be interpreted and operations can be adjusted as needed. Many oil and gas production sites are remote with no workforce on-site, so this technology has proven to be invaluable in the field of data collection and process control.

"SCADA’s ability to collect data at remote oil and gas sites reduces personnel visits and leads to route and dispatch optimization. But the profile of SCADA is changing in oil and gas. Today, as it is already seen in other process industries, SCADA is a platform technology used to control and supervise many types of industrial processes but also to optimise complex coordination of operations among multiple business partners."

Darren Schultz, Director, SCADA, Oil, Gas, and Chemical, ABB, Inc.

What Are the Benefits of Oil and Gas Automation?

How Does SCADA Impact Various Oil and Gas Sectors?

Upstream

During the initial stages of oil and gas production (otherwise known as upstream), the main use of SCADA is data collection and monitoring. This data provides insight into the environment and equipment in use, even capable of identifying the oilfield breakthrough moment. By monitoring the pressure levels, this technology safeguards the process itself along with the machinery being used. Using SCADA, the software can be programmed to power down the machinery in the event of an emergency. Likewise, the software allows for a more hybrid approach to decision making, offering an alert feature so a Site Manager may evaluate the situation for themselves prior to making a final decision. For instance, if a blow-out occurred and damaged a crucial piece of equipment, this stage would be delayed while a replacement is sourced, delivered and integrated into the system architecture, further impacting mid and downstream sectors. A fast decision and preventative maintenance minimises this risk.

As extraction begins, intricate separation of the oil from sand and water must be carried out, involving specialist machinery which spins and filters the crude oil. SCADA monitors this process, ensuring it is carried out safely and correctly without anomalies which could heavily affect the end product.

Midstream

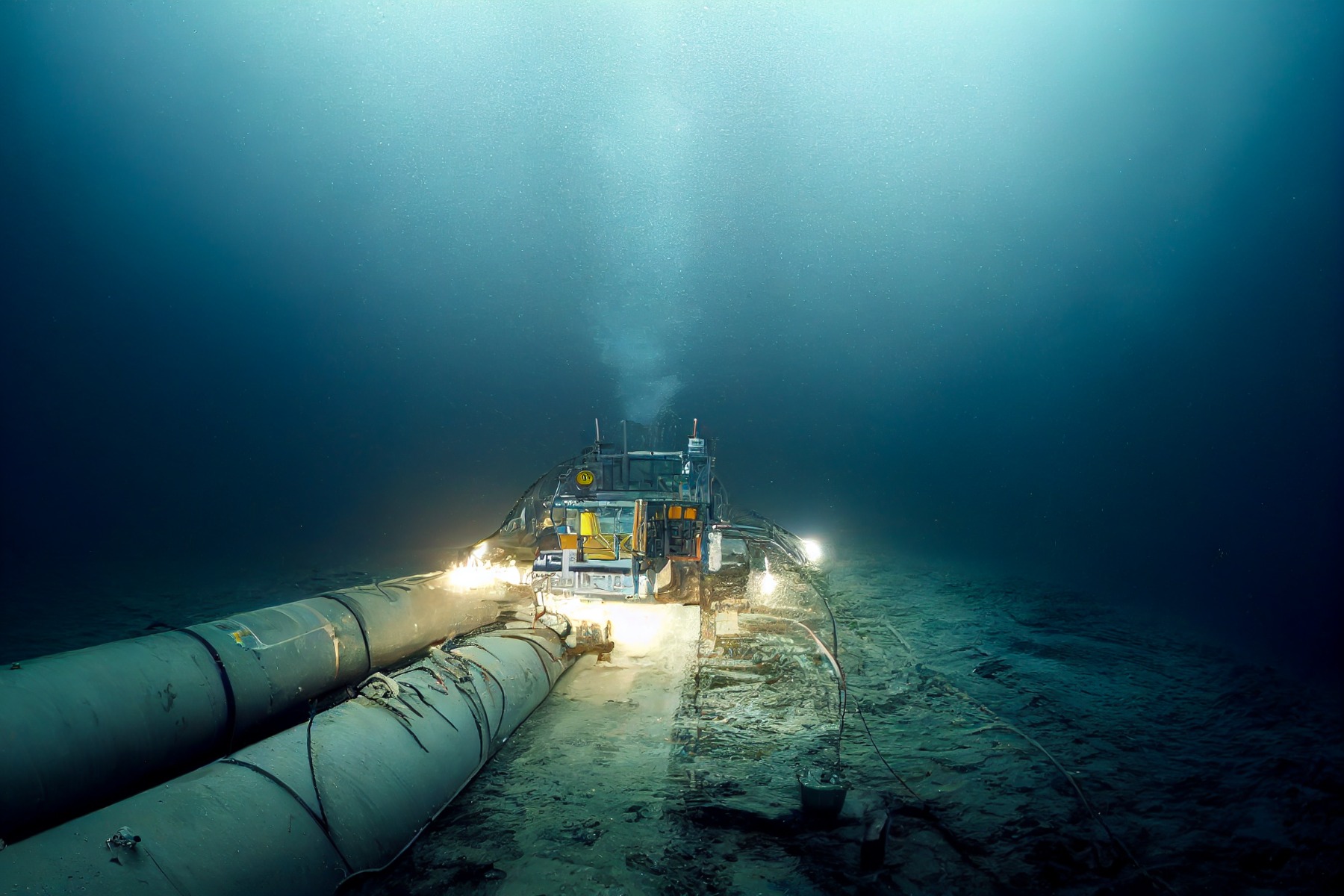

Having processed the crude oil, the next phase involves the transportation of the product, known as midstream which is the fastest growing area in the realm of SCADA with more significant growth opportunities on the horizon. Pipelines are frequently situated in brutal conditions across many thousands of miles, working conditions which would pose a safety threat to a human workforce. Hence the importance of SCADA and automated technologies.

On its journey downstream, oil flow is tracked by the SCADA system utilising field instruments. Many devices are incorporated into this data transmission system, however arguably the most important are pressure and temperature sensors. Temperature control is pivotal as dangerous levels of heat can collect within the pumps, potentially resulting in unplanned downtime and a dangerous event if left unattended. If a leak is detected, steps can be taken to fix the issue before it escalates to a far more serious issue, allowing Maintenance Managers to enforce a strong preventative maintenance schedule. Having reliable data and control systems in place holds the power to significantly reduce this risk and keeps the extracted goods in optimum condition for the consumer.

Downstream

The final stage of the process is crude oil refinement where it is transformed into an end product such as diesel oil or petroleum gas. These plants are often operating constantly so automating the process is heavily beneficial. SCADA systems oversee PLCs or RTUs throughout and essentially prepare the plant for the refinement process. Data is sent to said plant, pinpointing the level of product inflow, communicating the information to the necessary field devices such as sensors before the refinement begins.

Are you tired of trying to strike oil with a reputable industrial automation supplier? Look no further.

Whether you are on the hunt for a new PLC, HMI or some new temperature sensors, we have over 25 million parts available globally from thousands of manufacturers.

Want to find out more?

If you'd like to learn more, click the button below and one of our helpful friendly team will be in touch. Alternately you can reach us by phone on +44 800 234 3747

Share this article