Coronavirus Update - Business as Usual

Given the increasing disruption caused by Coronavirus, we wanted to reassure you that Northern Industrial remains available to support you and your business during these difficult times.With one of the largest stocks of new and obsolete industrial automation parts tested and ready to ship, we are confident we can continue to support you and your business. With robust contingency plans now in place it’s business as usual at Northern Industrial.

- One of the largest end-of-life / obsolete automation spare parts stock holdings in Europe

- 40 skilled bench Engineers to repair, test and service your parts

- Telephone support for any automation breakdown advice you need

- New stock of Control Techniques, Danfoss and Beijer products, and many more

- Key partner relationships with logistics experts such as Fedex, and same-day networks to get your parts to you - fast

- Contingency plans to ensure continued service

Our Customer Support Team will be contactable via phone, live chat and email during extended opening hours of 07:00 am - 09:00 pm Monday to Friday. You can check our stock levels, delivery times and prices online, and our delivery partner, FedEx, is available for express UK and international deliveries.

We take our responsibility to continue supporting manufacturing and vital supply chains during these exceptional circumstances very seriously. Since 1978 our aim has been to minimise downtime across industry, and never has this been more pertinent. We’ll keep you updated with any developments and wish all our customers, partners and suppliers the very best during this challenging period.

Download our Covid-19 risk assessment

Contact Us

Complete the form below to send us a message and one of the team will get back to you. Alternatively you can email us on [email protected]

Complete the form below to schedule a callback. Alternatively you can email us on [email protected]

11407 SW Amu St

Suite #M5855

Tualatin OR 97062-6884

United States

Mon-Thu: 1AM - 12PM CST

Fri: 1AM - 11AM CST

Delivery

Customers often ask if our lead times are accurate, and the answer is - yes!

We ship our products all over the world with fast FedEx delivery.

Tracked delivery so you can follow the journey

Securely packed to ensure safe delivery anywhere in the world

Shipping is free throughout Europe with a flat fee of £50/ €60/ $75 for the rest of the world

Free shipping applies to items weighing under 40kg. For heavier items and palette shipments, a bespoke shipping cost will be provided.

Need a part faster than it says online? Get in touch with our customer care team who will be happy to expedite your order where possible.

Select a destination from the drop down below to see the typical lead time for this part to reach any country in the world.

| Shipping to: | |

|---|---|

| Cost: | Standard Delivery - $75 |

| Arrival: | 3 days after despatch |

| 4 days after despatch | FREE Next day delivery |

| 5 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - €60 |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 5 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - €60 |

| 4 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 2 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | FREE Next day delivery |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 6 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - €60 |

| 5 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 10 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 11 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 5 days after despatch | FREE Next day delivery |

| 3 days after despatch | FREE Next day delivery |

| 2 days after despatch | FREE Next day delivery |

| 10 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 6 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | FREE Next day delivery |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 5 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 7 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | FREE Next day delivery |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | FREE Next day delivery |

| 2 days after despatch | FREE Next day delivery |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| 1 day after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 1 day after despatch | Standard Delivery - €60 |

| 7 days after despatch | Standard Delivery - $75 |

| 6 days after despatch | Standard Delivery - €60 |

| 11 days after despatch | Standard Delivery - $75 |

| 10 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | FREE Next day delivery |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 5 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| 2 days after despatch | FREE Next day delivery |

| 6 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | FREE Next day delivery |

| 3 days after despatch | FREE Next day delivery |

| 1 day after despatch | FREE Next day delivery |

| 5 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 3 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 5 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | FREE Next day delivery |

| 2 days after despatch | FREE Next day delivery |

| 4 days after despatch | FREE Next day delivery |

| 6 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 9 days after despatch | Standard Delivery - €60 |

| 4 days after despatch | Standard Delivery - €60 |

| 3 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - €60 |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 10 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| 6 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 10 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 2 days after despatch | FREE Next day delivery |

| 3 days after despatch | FREE Next day delivery |

| 7 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 7 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 3 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 6 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - €60 |

| 5 days after despatch | Standard Delivery - €60 |

| 10 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 3 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | FREE Next day delivery |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | FREE Next day delivery |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 3 days after despatch | FREE Next day delivery |

| 8 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 5 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 9 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 8 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - €60 |

| 4 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| 5 days after despatch | Standard Delivery - €60 |

| 7 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 3 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | FREE Next day delivery |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 3 days after despatch | Standard Delivery - $75 |

| 4 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 9 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| Contact us for accurate shipping information | Contact us for accurate shipping information |

| 4 days after despatch | Standard Delivery - $75 |

| 7 days after despatch | Standard Delivery - $75 |

| 8 days after despatch | Standard Delivery - $75 |

Country/Region Settings

Currency Settings

What do our product conditions mean?

New items are independently sourced to ensure you always get the best possible prices, and as you’d expect, have never been used. Due to the age of some of our obsolete items, original packaging seals may be broken. Our sales team are happy to confirm the status of the packaging before purchase. Items classed as new are backed up by Northern Industrial’s renowned comprehensive 2 year warranty. Peace of mind guaranteed!

Refurbished items are used but have been fully refurbished by our expert in-house engineers. This means that all of the key serviceable components have been replaced with high-quality new ones. The items are then cleaned, thoroughly tested and come with a full 2 year warranty.

Get your faulty part repaired with our expert repair service. Our standard repair service offers great value for money while our express service is geared for customers in a breakdown situation. During the repair process, our engineers will perform a full preventative maintenance service to ensure longevity. All of the key serviceable components are replaced with high-quality new ones and the items are then cleaned and thoroughly tested. All repairs are backed by the same great 2 year warranty we provide with new items!

We are authorised distributors for Control Techniques, Danfoss & Beijer. All other new components and parts supplied by us are sourced independently by our expert procurement team and are backed by our renowned comprehensive 2 year warranty. We are not an authorized distributor, reseller or representative for any manufacturer listed on the website.

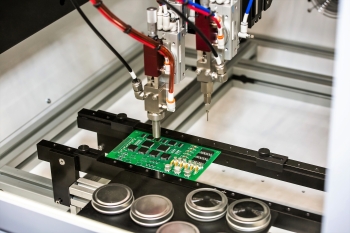

Repairs

Here at Northern Industrial we’ve been repairing industrial automation parts for over 40 years. We’ve helped companies big and small overcome downtime with long-lasting repairs, and can help you too! Our repair service includes:

Our unique 'No Fix No Fee' promise is exactly as it sounds. If we can't fix it, you don't pay anything.

If possible we will back up the program and parameters from your faulty unit before proceeding with the repair.

For extra peace of mind, our industrial electronic repairs are backed by an all-inclusive 2 year warranty.

With over 40 years in the automation spares and repairs business, we’ve encountered and fixed almost every fault that can occur on your automation parts.

As well as fixing the fault we also replace all serviceable components such as capacitors, fans and relays so that you can get the maximum lifespan out of your equipment.

Be 100% confident in the quality of our industrial electronic repairs thanks to our ISO 9001 accreditation.

The price you see is the price you pay. With no hidden charges or inspection fees, you can be sure of no hidden nasty surprises.

Whether you go ahead with the repair or not, we return your parts anywhere in the UK and Europe free of charge (subject to size and weight restrictions)

Knowledge Base

Expert articles, tips and advice

All Articles

Automation

General

14/04/2023

Automation in the Pipeline: How Has SCADA Refined the Oil and Gas Industry?

SCADA systems have transformed the oil and gas industry, forming a symbiotic relationship between automated technologies and the production process.

Automation

General

27/03/2023

Northern Industrial Joins Radwell International

Northern Industrial has come a long way since supporting local manufacturers with electronics repairs in 1978. Now, the time has come for us to expand further as we continue the fight against downtime.

Automation

General

17/03/2023

Circular & Lean Manufacturing Principles: Why Going Around In Circles Isn’t Always A Bad Thing

How does a cyclical, lean manufacturing approach benefit industrial automation and how can you give excessive e-waste its marching orders?

Automation

General

03/03/2023

Engineering a Standardised Industrial Landscape: Automation and Quality Control

From waste reduction and accurate error detection to real-time data feedback and consistency, we are witnessing a paradigm shift to a digitised review process.

Automation

General

17/02/2023

The Power of Brand Image: Repositioning in a Circular Economy

How can shifting from the linear business model to a circular economy contribute to the enhancement of brand image in the world of industrial automation?

Automation

Obsolescense

03/02/2023

Eliminating Unplanned Downtime: Automate Your Obsolescence Management

Obsolesence management is integral to avoiding unplanned downtime. We have a solution to satisfy your automation spares cravings.

Automation

General

20/01/2023

How Has Industrial Automation Gained Traction in Tyre Manufacturing?

The saying “don't reinvent the wheel” may be applicable for many things, but that is exactly what these tyre manufacturers keen to monopolise the industry are doing.

Automation

General

06/01/2023

Has Additive Manufacturing Earned Its Racing Stripes?

Is additive manufacturing the key to securing a place on the winners podium? With performance being dictated by aerodynamics, 3D printing is the solution for teams aiming to accelerate to victory.

Maintenance

Automation

23/12/2022

What is conformal coating and why is it used in automation?

Purchased a new PCB? You would expect it to produce the results. If the board lacks a conformal coating, your expectations may well come crashing down as you are hit with a harsh and unforgiving reality.